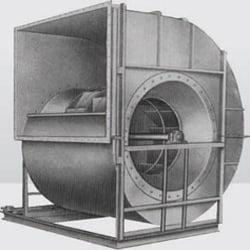

All arrangements are available with or without inlet boxes. Single width fans can be supplied in all arrangements. Double width fans can be supplied in arrangements 3 and 7.

Bearings

- Anti-friction self-aligning ball or spherical roller bearings. Grease or oil bath lubricated as required. Minimum L10 life of 50,000 hours.

- Where high radial and axial loads require, Dodge or equivalent sleeve oil bearings are used.

- Bearing accessories include thermocouples, RTDs, vibration probes & circulating oil lubrication if called for.

Couplings

- Where applicable, flexible gear type couplings are provided.

- Other flexible couplings are provided as specified, including steel grid, disc pack & flexible rubber element.

- All couplings are selected with a minimum 2.5 service factor.

Painting

-

A variety of surface preparations are available, including:

SSPC-SP 3, Machine Tool Prep

SSPC-SP 6, Uniform Grey Blast

SSPC-SP 10, Near White Blast -

And a variety of coatings such as;

Red Oxide Primer, Enamel, Epoxy, Spray Galvanising, FRP COATING, PP COATING

Shaft

- C-1030/1040/1045 alloy steel shaft, or special stainless alloy, depending upon the application. Where strength of materials is limited and corrosion protection is required, carbon steel shafts are clad with corrosion resistant alloys.

- Shaft designed for a first critical speed ratio of 1.25 minimum.

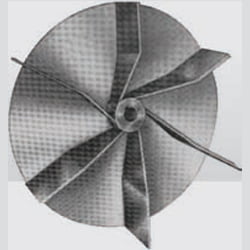

Rotor

- All plate fabricated, welded construction for durability.

- All butt welds full penetration.

Shaft Seals

Single and Multidisc Labyrinth Seals for Single Inlet Fans

- Standard shaft seal is a single disc.

- Suitable where minor amounts of gas leakage, in or out of the fan, are permissible.

- Multidisc designs used when a higher degree of sealing is required.

- Disc materials include Garlock, Durlon & other materials as specified by customer.

Mechanical Ring Seals for Single Inlet Fans

- Used where gas leakage must be kept to a minimum.

- Segmented Teflon or carbon rings are contained in a machined housing fabricated from carbon steel or corrosion resistant stainless alloys.

- Additional seals, including stuffing box seals are available for special applications.

Wear Protection

- In higher dust load applications, where excessive wear is a problem, PAF offers a variety of wear protection options.

Housing Protection

- Housing scroll fully lined, housing side plates partially lined with cheek plates.

- Wear plates are fully replaceable, installed in plug.

- Welded, studded or bolted segments.

- Inlet boxes and inlet cones may also be lined, depending upon the severity of the application.

- All joints and corners are seal pass welded to prevent channeling of dust stream.

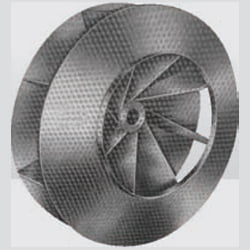

Backward Inclined Blades Type PB

Good efficiency with non overloading power characteristic Range:

Capacity: 600 to 8,00,000 M3/hr

St. Pressure: Upto 250mm of wg

Wheel Dia: 200 to 2762 mm

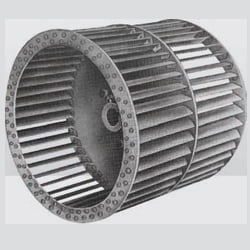

Forward Curved Blades Type PF

Large amount of air volume at lower speed Range:

Capacity: 20 to 1,20,000 M3/hr

St. Pressure: Upto 250mm of wg

Wheel Dia: 25 to 927 mm

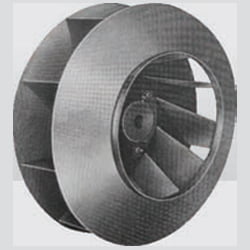

Airfoil Blades Type PA

Highest efficiency with non-over-loading power characteristics

Range:

Capacity: 11,900 to 8,00,00 M3/hr

St. Pressure: Upto 1800 mm of wg

Wheel Dia: 500 to 2762 mm

Performance Testing

Centrifugal Fans and Blowers: As per IS 4894, AMCA – 210 BS – 848

Dynamic Balancing: AS per ISO – 1940 (E) Gr. 6.3 OR Gr. 2.5

Fans for Industrial / Conveying Application

Model: EX / EY / EZ / EW

Impeller Type

Range

Capacity: 450 TO 2,30,000 M3/hr

St. Pressure: Upto 500 mm of wg

Wheel Dia: 311 to 2648 mm

EX

Highest efficiency with backwardly inclined radial tip. Blades to handle air and fine dust particles etc.

EY

With radial blades to handle air or gas containing granular material.

EZ

Used for handling metal chips, wood shaving, fibres etc.

EW

With open type radial blades used to handle air with heavy and light dust.

Performance Testing

Centrifugal Fans and Blowers: As per IS 4894, AMCA – 210 BS – 848

Dynamic Balancing: AS per ISO – 1940 (E) Gr. 6.3 OR Gr. 2.5